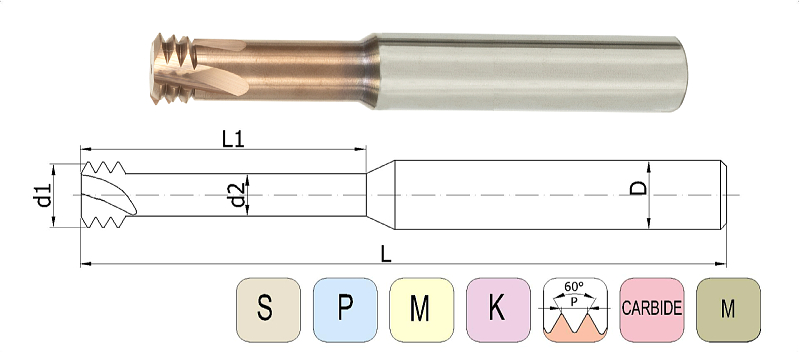

CNC de 60 grados de acero tungsteno con fresado de rosca de tres filas

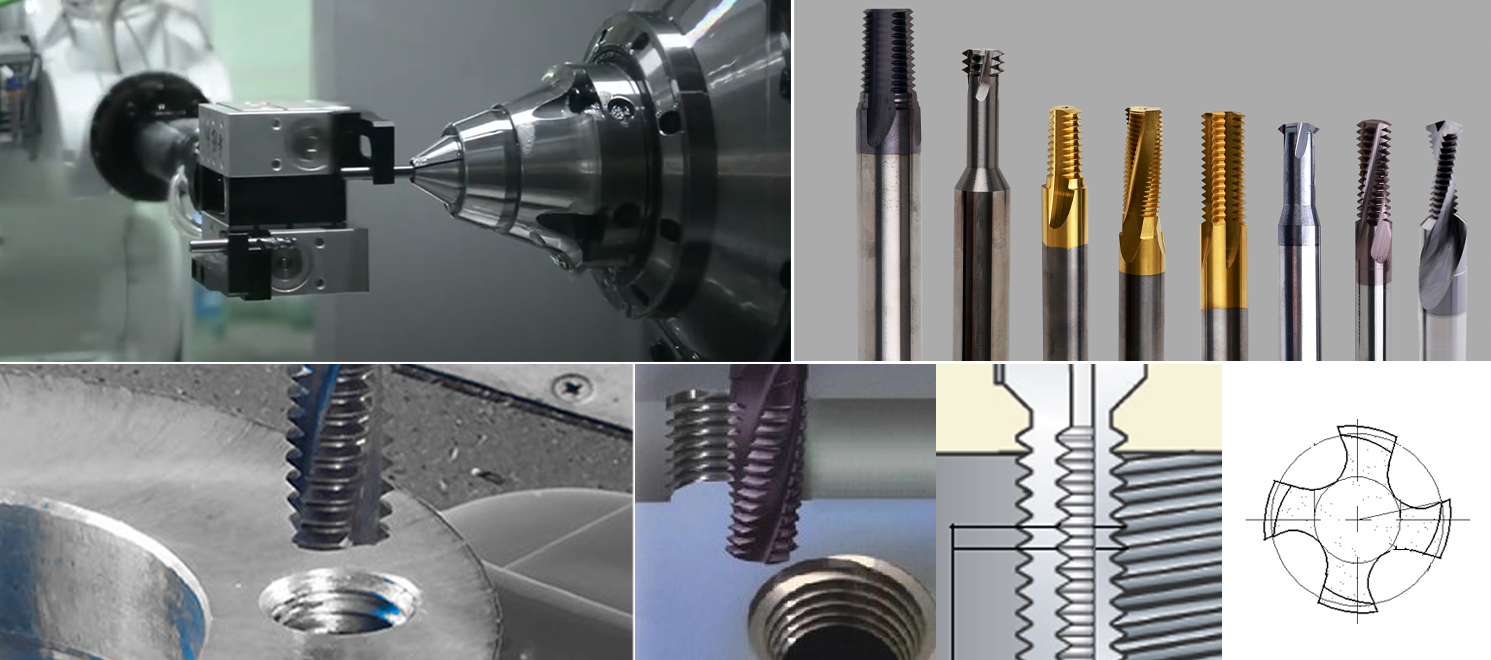

Máquinas aplicables:

Programación y uso de equipos como máquinas de grabado, máquinas de alta velocidad, máquinas para caminar, centros de mecanizado CNC, etc.

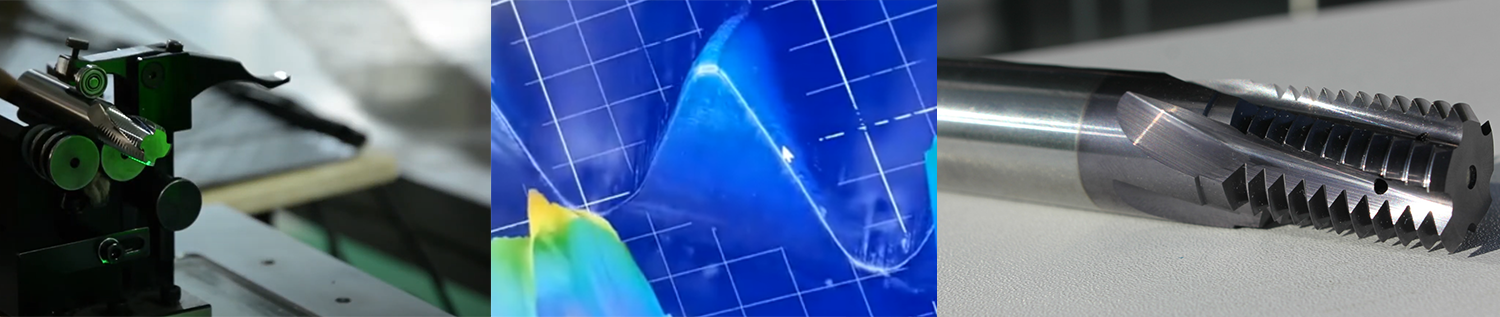

Materiales aplicables:

Acero al carbono, acero de aleación, hierro fundido, acero inoxidable, temperatura alta, aleación de titanio de aleación.

Utilizamos materiales de acero de tungsteno para garantizar la estabilidad de los productos de las materias primas.

Haga coincidir el recubrimiento apropiado de acuerdo con los materiales de la pieza de trabajo. Gracias al equipo de molienda de rosca de alta precesión para asegurarse de una calidad estable para nuestros productos.

| Ltemno. | Presupuesto | d1 | d2 | L1 | L | D | Z |

| T0.25 0.732450X | M1.0*0.25 D0.73*2*D4*50*3f | 0.73 | 0.43 | 2 | 50 | 4 | 3 |

| T0.25 0.922.4450X | M1.2*0.25 D0.92*2.4*D4*50*3F | 0.92 | 0.62 | 2.4 | 50 | 4 | 3 |

| T0.3 1.052.8450x | M1.4*0.3 D1.05*2.8*D4*50*3f | 1.05 | 0.65 | 2.8 | 50 | 4 | 3 |

| T0.35 1.23.2450X | M1.6*0.35 D1.2*3.2*D4*50*3f | 1.2 | 0.78 | 3.2 | 50 | 4 | 3 |

| T0.35 1.43.6450X | M1.8*0.35 D1.4*3.6*D4*50*3f | 1.4 | 0.98 | 3.6 | 50 | 4 | 3 |

| T0.4 1.554450X | M2.0*0.4 d1.55*4*d4*50*3f | 1.55 | 1.05 | 4 | 50 | 4 | 3 |

| T0.45 1.75450X | M2.2*0.45 d1.7*5*d4*50*3f | 1.7 | 1.1 | 5 | 50 | 4 | 3 |

| T0.45 25450X | M2.5*0.45 d2*5*d4*50*3f | 2 | 1.45 | 5 | 50 | 4 | 3 |

| T0.5 2.46450X | M3.0*0.5 d2.4*6*d4*50*3f | 2.4 | 1.8 | 6 | 50 | 4 | 3 |

| T0.6 2.758450X | M3.5*0.6 D2.75*8*D4*50*3f | 2.75 | 2 | 8 | 50 | 4 | 3 |

| T0.7 3.158450X | M4.0*0.7 D3.15*8*D4*50*3f | 3.15 | 2.3 | 8 | 50 | 4 | 3 |

| T0.75 3.59450X | M4.5*0.75 d3.5*9*d4*50*4f | 3.5 | 2.55 | 9 | 50 | 4 | 4 |

| T0.8 410450X | M5.0*0.8 d4*10*d4*50*4f | 4 | 3 | 10 | 50 | 4 | 4 |

| T1.0 4.812650X | M6.0*1.0 D4.8*12*D6*50*4f | 4.8 | 3.6 | 12 | 50 | 6 | 4 |

| T1.0 616650X | M8*1.0 D6*16*D6*50*4F | 6 | 4.8 | 16 | 50 | 6 | 4 |

| T1.25 616650X | M8*1.25 D6*16*D6*50*4F | 6 | 4.5 | 16 | 50 | 6 | 4 |

| T1.0 820860X | M10*1.0 D8*20*D8*60*4F | 8 | 6.8 | 20 | 60 | 8 | 4 |

| T1.5 820860X | M10*1.5 D8*20*D8*60*4F | 8 | 6.2 | 20 | 60 | 8 | 4 |

| T1.0 10241075X | M12*1.0 D10*24*D10*75*4F | 10 | 8.7 | 24 | 75 | 10 | 4 |

| T1.5 10241075X | M12*1.5 D10*24*D10*75*4F | 10 | 8.1 | 24 | 75 | 10 | 4 |

| T1.75 10241075X | M12*1.75 D10*24*D10*75*4f | 10 | 7.8 | 24 | 75 | 10 | 4 |

| T1.5 12281275X | M14*1.5 D12*28*D12*75*4f | 12 | 10.1 | 28 | 75 | 12 | 4 |

| T2.0 10281075X | M14*2.0 D10*28*D10*75*4F | 10 | 7.5 | 28 | 75 | 10 | 4 |

| T2.0 12321275X | M16*2.0 D12*32*D12*75*4f | 12 | 9.5 | 32 | 75 | 12 | 4 |

| T1.5 143214100X | M16*1.5 D14*32*D14*100*4f | 14 | 12.1 | 32 | 100 | 14 | 4 |

| T2.0 13.53214100X | M16*2.0 D13.5*32*D14*100*4f | 13.5 | 11 | 32 | 100 | 14 | 4 |

| T1.5 164016100X | M20*1.5 D16*40*D16*100*4f | 16 | 14.1 | 40 | 100 | 16 | 4 |

| T2.5 164016100X | M20*2.5 D16*40*D16*100*4f | 16 | 12.6 | 40 | 100 | 16 | 4 |

| T3.0 164816100X | M24*3.0 D16*48*D16*100*4f | 16 | 12 | 48 | 100 | 16 | 4 |

| T0.25 0.733450X | M1.0*0.25 D0.73*3*D4*50*3f | 0.73 | 0.43 | 3 | 50 | 4 | 3 |

| T0.25 0.923.6450x | M1.2*0.25 D0.92*3.6*D4*50*3F | 0.92 | 0.62 | 3.6 | 50 | 4 | 3 |

| T0.3 1.054.2450x | M1.4*0.3 D1.05*4.2*D4*50*3f | 1.05 | 0.65 | 4.2 | 50 | 4 | 3 |

| T0.35 1.24.8450X | M1.6*0.35 D1.2*4.8*D4*50*3f | 1.2 | 0.78 | 4.8 | 50 | 4 | 3 |

| T0.4 1.556450X | M2.0*0.4 d1.55*6*d4*50*3f | 1.55 | 1.05 | 6 | 50 | 4 | 3 |

| T0.45 27.5450x | M2.5*0.45 D2*7.5*D4*50*3f | 2 | 1.45 | 7.5 | 50 | 4 | 3 |

| T0.5 2.49450X | M3.0*0.5 d2.4*9*d4*50*3f | 2.4 | 1.8 | 9 | 50 | 4 | 3 |

| T0.7 3.1512450X | M4.0*0.7 D3.15*12*D4*50*3f | 3.15 | 2.3 | 12 | 50 | 4 | 3 |

| T0.8 415450X | M5.0*0.8 d4*15*d4*50*3f | 4 | 3 | 15 | 50 | 4 | 3 |

| T1.0 4.818650X | M6.0*1.0 D4.8*18*D6*50*4f | 4.8 | 3.6 | 18 | 50 | 6 | 4 |

| T1.25 624650X | M8*1.25 D6*24*D6*50*4F | 6 | 4.5 | 24 | 50 | 6 | 4 |

| T1.5 830860X | M10*1.5 D8*30*D8*60*4F | 8 | 6.2 | 30 | 60 | 8 | 4 |

| T1.75 10361075X | M12*1.75 D10*36*D10*75*4f | 10 | 7.8 | 36 | 75 | 10 | 4 |

Escriba su mensaje aquí y envíenoslo